SIVACON 8PS TRUNKING SYSTEMS

LDM-P system

Cost-efficient and safe link between transformers and inverters in photovoltaic stations

Sustainable power distribution in solar applications

Photovoltaic stations (PV stations) are characterised by a high power volume in the smallest space. Furthermore, such stations must ensure a high availability and operational safety while at the same time keeping maintenance requirements as low as possible. And, not the least, the corre- sponding modules shall be produced in large quantities in a standardised way optimised for production. Especially for high currents, busbar trunking systems have prevailed as an efficient, safe, and standard-compliant alternative to classical cables in many areas of application.

With the LDM-P system, Siemens now also opens up the characteristic potentials of this technology for photovoltaic stations.

Equally, the use for further container solutions is possible, in which the busbar trunking system is mounted in a protected way.

Proven solution, further developed

The LDM system – originally designed for wind turbines – was developed further

for specific applications. One innovation of the LDM-P versions lies in the fact that this system, which was conceived for use in closed stations, works without housings.

It is designed for current ratings up to 7,000 A.

As the connections between the busbar and the transformer on one side or the converter on the other side are not standardised, every LDM-P application is a customer- specific solution.

Advantages for efficient use

Three advantages predestine busbar trunking systems for use in photovoltaic stations: efficient power transmission at high currents, low fire load, and the high safety standards of a design verified low-voltage switchgear and controlgear assembly in accordance with IEC 61439. In addition, material costs for aluminium are below those for copper cables. The LDM-P busbar trunking system now offers a corresponding solution especially for OEMs in the solar industry.

Connection piece, on the transformer side

Straight length between inverter and transformer

System

LDM-P13 LDM-P14. LDM-P16 LDM-P24. LDM-P36

Regulations and standards

IEC/EN 61439-1/-6

Rated operational voltage Ue

1,000 V

Rated current Inc. [A] @35°

PE conductor

no

Degree of protection

Housing

Short-circuit rating

Rated short-time withstand

current 0.1 s. Icw

Ipk

Ambient temperature

Cross-section per phase [mm2]

Weight [kg/m]

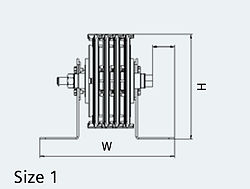

Dimensions (incl. supports). [mm] W

D

Drawing (schematic sketch)

@50°

1800 2500 2900 4200 7000

1600 2300 2700 3900 6600

IP00

Without housing (protection of persons must be

ensured by measures on site)

105 kA

50 kA

min. -5° C/max. 45° C

698 1014 1203 2028 3609

~8.5 ~11.5 ~13 ~20 ~33

244 301 358

191

Size 1 Size 2 Size 3

Technical data

Busbar coating | Epoxy | 19 | ||||||

Insulation | Air-insulated | 18 | ||||||

Mounting Position | Vertical, horizontal | 17 | ||||||

Standards | IEC 61439-1/-6 | 16 | ||||||

Housing material | - | 15 | ||||||

Conductor material | Aluminium | 14 | ||||||

Connection technology | Single-bolt clamped connection with hook and bolt connection | 13 | ||||||

Data transmission | - | 12 | ||||||

Tap-off unit | - | 11 | ||||||

Tap-off point | - | 10 | ||||||

Fire load (per tap-off point) | - | 9 | ||||||

Fire load | Depending on the application | 8 | ||||||

Number of conductors | 3 to 9 conductors | 7 | ||||||

Rated short-time withstand current Icw (1s) | 50 kA | 6 | ||||||

Rated peak withstand current Ipk | 105 kA | 5 | ||||||

Rated current InA | 1,800 A to 7,000 A | 4 | ||||||

Degree of protection | IP00 | 3 | ||||||

Rated operational voltage Ue | 1,000 V AC | 2 | ||||||

Rated insulation voltage Ui | 1,000 V AC | 1 |

Your benefit

-

Modular system for individual customer requirements

-

Pre-defined impedances and stipulated technical features

-

Efficient installation

-

Compact, maintenance-free

-

busbar trunking systems